|

|

02-10-2013, 03:38 AM

|

|

|

|

Join Date: Jan 2012

Location: Valleyview AB

Posts: 1,376

|

|

Step by step reloading for beginners

Step by step reloading for beginners

Midnight Saturday, just got home from a long shift at work and decided to do a little hand loading demonstration.

To start with, set up a full length sizing die in the press following the manufacturers instructions.

Our next step is to lubricate the cases, you can use just about anything for a lubricant, just remember that whatever you use must be able to be cleaned off. My personal preference is Imperial sizing die wax but for large batches on our progressive we use a non stick cooking spray for economy purposes.

Now all we do is run the brass into the full length sizing die until the shell holder bottoms out on the die, then pause for a second and lower the ram to remove your freshly sized case.

After you full length resize your brass for the first time it will probably need to be trimmed. Consult a loading manual to find out what the maximum trim length for your specific brass is.

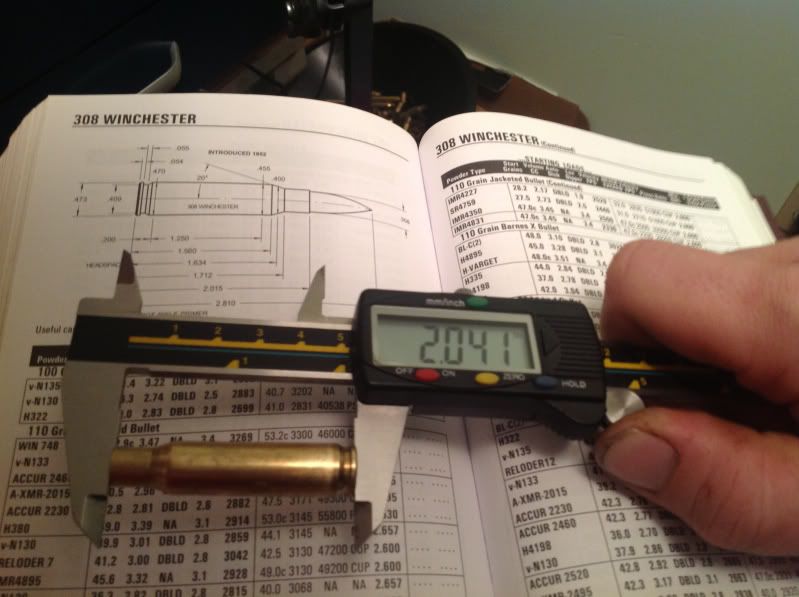

In this case we are reloading 308 Winchester in once fired federal brass. Our maximum length for the case is 2.015". While most of our brass is very close to that size, some of it is in excess of .030" which is dangerously long that need to be trimmed so that every piece of brass is a consistent length.

I use a Lee trimmer that can be attached to a drill. They are very simple and inexpensive but only trim to one pre set length.

So there we have it, most of the Lee trimmers that I have used will trim your bras from .005" to .010" under the maximum trim length. I have used other trimmers that are adjustable and some brass was trimmed a little bit too short but as long as its no more than roughly .020" under what the book says I don't think it would ever be a problem to shoot.

So now that our brass has been resized and trimmed to length we will chamfer the inside and outside of the case. What I am doing in this batch of reloads is working up a hunting load for this coming fall season for my savage 308. The load I want to try is 180 grain bullet over a Winchester large rifle primer and Varget powder.

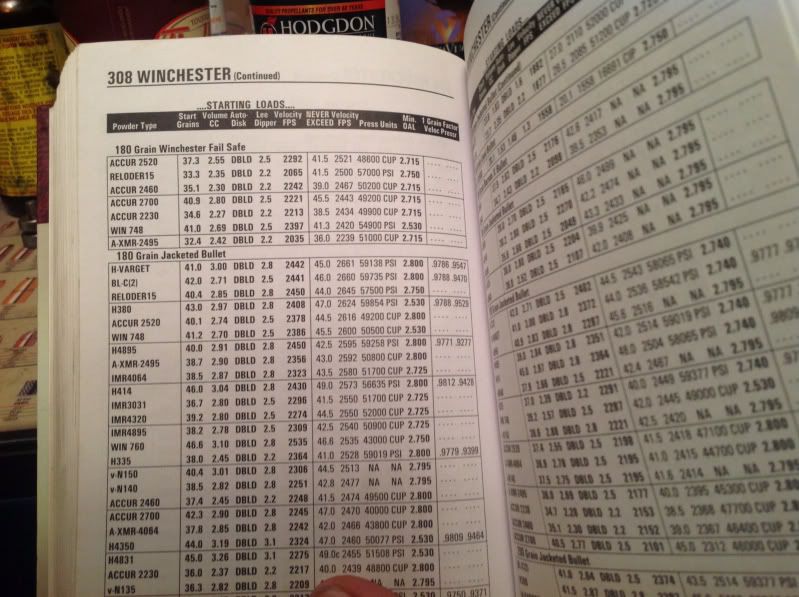

My manual says the starting load is 41 grains of powder and the maximum load is 45 grains with a minimum overall length of 2.800", now that I have chosen my load I will prime my cases and get my scale setup

*Warning*

USE THE STARTING LOAD AND WORK UP

When you prime your brass you should watch for primers that push in with little to no effort, that is a sign of a worn primer pocket and it makes the brass unsafe to shoot. You should flatten the brass with the worn primer pockets and discard.

It is extremely important to zero your scale every single time you start a new batch. Once your scale is set up and zeroed it should not be moved until you are finished.

Starting from zero we follow the instructions to set the scale for our desired weight, once I dial that in I set my powder thrower to throw a charge just under my goal and use my Lyman trickler to get the charge weight perfect on the scale, you don't need a trickler, I use a spoon more often then anything else but it makes for a pretty picture!

Once we have our charge measured its time to dump it into a primed case and setup our bullet seating die, you can practice on empty unprimed but resized cases to get the OAL correct and keep one as a dummy round to setup the die next time but once you have done this a few hundred times you get a pretty good feel for making small adjustments until its where you want it.

And there we have it, fresh off the press hand loaded test round #1

A word on Over All Length

A word on Over All Length

Bullet length varies, I have never found a batch of Sierra Hornady or Berger bullets that were the same length consistently, but that's ok...

Bullets aren't seated into the case by there tip, they are pushed into the case mouth on the area close to where the bullet tapers out to its true maximum diameter, to measure that accurately you need a tool that measures from that point to the base of the case and such tools are available but I won't get into that at this point.....

For the average Joe or Jane who wants to get into loading there own ammo I suggest you use the OAL listed in the book, setup your seating die and measure the first round so it's close to perfect and just run with it, as long as your OAL doesn't exceed .020" and keep growing then chances are all your seeing is a variation or imperfection in the very tip of the bullet.

This is meant to be a step by step for the novice reloader, if you have questions please ask and I will do my best to answer... If I get a positive response I will go more in depth into things such as die setup for various different effects and maybe even a step by step for precision reloading.

|

02-10-2013, 07:54 AM

|

|

|

|

Join Date: May 2011

Location: moving to quesnel

Posts: 3,013

|

|

reloading is something i am very interested in .. thanks for taking the time to put this thread and all the pictures together.

wayne

__________________

Do not squander time, for that is the stuff life is made of.......Ben Franklin

|

02-10-2013, 09:20 AM

|

|

|

|

Join Date: Jan 2012

Location: st paul alberta

Posts: 278

|

|

nice job bud this sure will help alot of beginners cheers

|

02-10-2013, 09:27 AM

|

|

|

|

Join Date: Oct 2012

Location: 4626w4

Posts: 186

|

|

Lee trimmer

Lee trimmer

Nice job just getting into reloading. Could you tell us more about the lee trimmer sounds like I will need one.Thanks

|

02-10-2013, 09:57 AM

|

|

|

|

Join Date: Jan 2011

Posts: 1,923

|

|

Quote:

Originally Posted by Jeremy403

Nice job just getting into reloading. Could you tell us more about the lee trimmer sounds like I will need one.Thanks

|

They work great. I use them all the time. Like the OP stated they only trim to one size but they are super fast and pretty accurate. They cost about $6 for the pilot and $15 or so for the holder and the mill. But once you have the holder and mill you only need to buy a new pilot to trim a new caliber.

|

02-10-2013, 09:58 AM

|

|

|

|

Join Date: Dec 2010

Location: Look behind you :)

Posts: 27,843

|

|

Quote:

Originally Posted by Jeremy403

Nice job just getting into reloading. Could you tell us more about the lee trimmer sounds like I will need one.Thanks

|

Lee trimmers are all chambering specific. So you will need one for each type you reload for....very easy to use and usually around $8 for each individual one.

**edit....posted same time as ShawnM

LC

__________________

|

02-10-2013, 10:03 AM

|

|

|

|

Join Date: Dec 2008

Location: Camrose

Posts: 46,549

|

|

Just to add a few points:

-Not all loads listed in all manuals will be safe in all rifles. That is why you start at the minimum load, and work up.

-It is very important to learn to recognize pressure signs. Pressure signs can be seen in several forms, from heavy bolt lift after firing, to extrusion marks on the case head,to excessive case head expansion, to loose primer pockets after only a few loads. I recommend that a new loader does some research online, to find more information on identifying pressure signs. If you notice pressure signs, stop shooting, until you deal with the pressure issue.

-Those loose primer pockets are not worn primer pockets, they are stretched primer pockets. If you encounter loose primer pockets after only a few loadings, your loads are too hot.

-Be sure to avoid lube on the shoulder of the case, as lube on the shoulder will cause dents in your cases. If you are seeing dents in the shoulders, clean your sizing die.

-Be sure to learn how to adjust your seating die properly. A properly adjusted seating die will not contact the shoulder of a sized case. Adjusting the seating die incorrectly will push back the shoulder, and possibly bell it, so the rounds won't chamber.

-The COL can be very important as far as obtaining the best accuracy from a firearm, and the COL listed in the manuals will seldom provide the best accuracy in your firearm. The best COL for your firearm,can only be determined with your firearm.

-The velocities, and supposed "most accurate load" listed in a manual, are for that specific firearm, and those specific lots of components, and they can vary significantly in your firearm.

-When you change any component, back off the powder charge, and work up the load again.

-Loads that are perfectly safe in cool temperatures, can cause excessive pressures in warm temperatures.

-Since pressure signs don't usually appear until you are well past the normal operating pressure for the cartridge, I like to back off the powder charge until they disappear completely, and then back off a little more.

__________________

Only accurate guns are interesting.

Last edited by elkhunter11; 02-10-2013 at 10:21 AM.

|

02-10-2013, 11:26 AM

|

|

|

|

Join Date: Mar 2012

Location: Edmonton, AB

Posts: 280

|

|

here are some common pressure signs i think i found on this forum a little while back!

-Case bulging, particularly near an unsupported part of the head.

-Case crack along side (may mean excess pressure, but may mean brittle, defective, draw mark scored, or worn out brass).

-Case head expansion (CHE; may mean high pressure, may mean nothing in isolated case).

-Case head separation (may mean high pressure, but may mean excess headspace or worn out brass).

-Case splits in body in fewer than 10 reloads-back loads down at least 2% (can also be due to ammonia vapor exposure or a brass defect in an individual case).

-Case mouth split (may mean high pressure, but more often means case needed neck annealing).

-Case pressure ring expansion (PRE; not much more reliable than case head expansion but may mean pressure is excessive).

-Case primer pockets getting loose in five reloads or fewer.

-Case, excessive stretching (this is actually visible pressure ring area stretching which may be due to excess pressure or to excess headspace).

-Case, extractor or ejector marks on head, especially after increasing powder charge. Most common in semi-auto rifles, but can happen with any extractor and ejector (may be high pressure or bad timing, or an extractor standing proud on the bolt face).

-Case, won’t fit back into chamber after firing.

-Gas leak (see Primer Leaking, below).

-Groups start to open up at or beyond a suspected maximum load pressure.

-Hard bolt lift.

-Incipient case head separation (starting or partial case head separation or signs of it).

-Increase in powder charge gets unexpected velocity. Look for an orderly progression of muzzle velocity vs. charge weight. If muzzle velocity stops going up or actually goes down, or if it goes up too much, you have a problem. The first two indicate steel is stretching. The stretch may just be due to uneven bolt lug contact, or it may mean you are stretching the receiver and fatiguing the steel abnormally. Unexpected velocity increase indicates unexpected pressure increase. With any abnormal velocity, you should back the charge off 5% from where it started. If, based on manuals, the load and its velocity seem too low for this to be happening, get your gun inspected or bolt lugs lapped and try working up the load again.

-Primer blown (primer falls out when gun is opened; same as loose primer pocket).

-Primer cratering (may mean high pressure, or it may mean a worn firing pin or firing pin tunnel, or may mean you have a new production Remington bolt with chamfered firing pin tunnel).

-Primer flattening (may mean high pressure, or may mean long headspace; some loads always make flat primers; softer primer cups (Federal) flatten more easily than harder ones (CCI), so it also can mean nothing at all).

-Primer, mushrooming (may mean high pressure, or may mean long headspace).

-Primer, piercing (may mean high pressure or may mean incorrect firing pin protrusion or incorrect firing pin nose shape).

-Primer, leaking gas around primer pocket (may mean high pressure, may mean loose primer pocket in case, may mean damaged primer was inserted, may mean primer backed out too far during firing, which excessive chamber headspace makes possible).

-Case, short life -back load off at least 2% (under 10 reloads in non-self-loaders or with military brass in self-loaders, 6 or less in self-loaders with commercial brass).

-Case, sticky or hard extraction (especially in revolvers this is a positive sign to knock the powder charge down at least 5%, in rifles also look for chamber ringing).

-Case, torn or bent rim (from hard extraction, see #24., above).

-Case, primer pocket expanded and won't hold newly seated primers firmly (PPE; this is likely no more accurate than CHE (3., above), but is a more sensitive measure for those with tools that can measure the inside diameter of a primer pocket repeatably to the nearest ten-thousandth of an inch).

-Primer, loose or falls out when opening the action or after (see # 26., above)

-Case, increase in required trimming frequency (this is an sudden increase in case length growth per load cycle, it can be caused by excess pressure, but can also be a sign of increasing head space due to some other problem. It is especially common as a pressure sign in lever action guns because the greater span from bolt face to rear lug allows more steel stretch when pressure gets excessive.)

-Case, increase in apparent headspace (this means the cases are coming out longer, including from casehead to shoulder. It can mean bolt lug setback, which is usually an extreme pressure sign. It can also mean a loose barrel or an improperly set Savage barrel. Whatever the cause, the gun should go straight to the gunsmith for inspection.)

-Gas or Flame Cutting of revolver top strap. (Can also be due to excessive barrel/cylinder gap that needs correction.)

-Gas or Flame cutting of rifle bolt face by gas leaks around primer pocket or of bolt face perimeter. (Can also be result of occasional leaks from normal rounds firing, as is observed in many military gun bolts.)

-Velocity higher than manual maximum load velocity for same powder and barrel length. For example: one fellow using a .243 Win load one charge increment below the manual maximum got velocity 200 fps higher than the manual claimed for its maximum load's velocity. His single-shot action was popping open at every shot. With QuickLOAD we were able to calculate he had about 77,000 psi. An alternate explanation, if everything else is normal, is that your chronograph readings are incorrect. It is not uncommon to get high readings due to muzzle blast when the chronograph is too close to the gun. I recommend 15 feet minimum, since that is what the manual authors typically use and is what you are comparing to. Some big magnum rifles need even more distance.

|

02-10-2013, 11:28 AM

|

|

|

|

Join Date: Jun 2007

Location: Ft. McMurray

Posts: 39,012

|

|

More threads like this would be a great asset to the forum, as opposed to the rant threads!

Great tutorial for the uninitiated and also great responses from those more experienced hand loaders!

Cat

__________________

Anytime I figure I've got this long range thing figured out, I just strap into the sling and irons and remind myself that I don't!

|

02-10-2013, 11:30 AM

|

|

|

|

Join Date: Mar 2012

Location: Edmonton, AB

Posts: 280

|

|

Quote:

Originally Posted by catnthehat

More threads like this would be a great asset to the forum, as opposed to the rant threads!

Great tutorial for the uninitiated and also great responses from those more experienced hand loaders!

Cat |

X2!!!

|

02-10-2013, 11:52 AM

|

|

|

|

Join Date: Jan 2012

Location: Valleyview AB

Posts: 1,376

|

|

Quote:

Originally Posted by catnthehat

More threads like this would be a great asset to the forum, as opposed to the rant threads!

Great tutorial for the uninitiated and also great responses from those more experienced hand loaders!

Cat |

I was just trying to keep it simple, I seem to get a PM weekly from someone interested in getting into reloading, this way instead of dealing with them one on one for the basic stuff they will have an idea of the steps....

This is just the brass tacks and I'm trying not to overwhelm a prospective Reloader with big words and negative points that might turn them away from the hobby....

I do ask that if your going to post tips in this thread to please include pictures as a visual aid.

|

02-10-2013, 12:13 PM

|

|

|

|

Join Date: Jun 2007

Location: Ft. McMurray

Posts: 39,012

|

|

Quote:

Originally Posted by Hotwheels81

I was just trying to keep it simple, I seem to get a PM weekly from someone interested in getting into reloading, this way instead of dealing with them one on one for the basic stuff they will have an idea of the steps....

|

I know exactly what you mean, there are many of us here who get PM's and questions every day on fire arms, handloading, shotguns, huntingn , etc, because they are tired of the open forum crap that some ,members seem to put out there when an honest question is asked.

Threads like this are super helpfull to those that want to learn....

Cat

__________________

Anytime I figure I've got this long range thing figured out, I just strap into the sling and irons and remind myself that I don't!

|

02-10-2013, 12:45 PM

|

|

|

|

Join Date: May 2012

Location: Fort McMurray

Posts: 2,138

|

|

Thank you. Was going to start a thread in the spring from a new reloader's point of view as a primer of the absolute basics beginnings as i learned going along. Glad you beat me to it so I won't have to.

Great job. More collaboration, less flame wars.

__________________

If you're reading this, why aren't you in the woods?

Stupidity is taxable and sometimes I get to be the collector.

|

02-10-2013, 04:55 PM

|

|

|

|

Join Date: Jul 2010

Location: North of Cochrane

Posts: 6,827

|

|

Great post and even better pictures

Great post and even better pictures

This lubricating business, some guys on here have never stuck a case, and I have broken a lee press like the one in the picture. Elk says to clean the die if you are getting dents, I am, I'll do that and see if that solves it.

I have the Lee trim parts but am unsure how to use the drill, or better yet a drill press. Do you just chuck the shell holder?

Again wonderful pictures and a great post.

__________________

"The well meaning have done more damage than all the criminals in the world" Great grand father "Never impute planning where incompetence will predict the phenomenon equally well" Father

|

02-10-2013, 08:37 PM

|

|

|

|

Join Date: Jan 2012

Location: Valleyview AB

Posts: 1,376

|

|

Quote:

Originally Posted by densa44

This lubricating business, some guys on here have never stuck a case, and I have broken a lee press like the one in the picture. Elk says to clean the die if you are getting dents, I am, I'll do that and see if that solves it.

I have the Lee trim parts but am unsure how to use the drill, or better yet a drill press. Do you just chuck the shell holder?

Again wonderful pictures and a great post.

|

Just like that...

And yes you should try cleaning your die, there is also a little relief hole in most dies that hides behind the lock ring that will expel excess lube... Unless its plugged up with dirt and gunk...

Sometimes some lubes will cause dents no matter how hard you try... I haven't had that issue with imperial wax yet... A little go's a long long way.

|

02-10-2013, 09:01 PM

|

|

|

|

Join Date: Jul 2010

Location: North of Cochrane

Posts: 6,827

|

|

I'll set mine up like yours

I'll set mine up like yours

Thanks very much, I haven't stuck a case for 2 years but that is a long way from never, every time I pull down on that sizing die I worry the case wont come out. I'll take the advice and use less lube and really give the dies a good cleaning.

__________________

"The well meaning have done more damage than all the criminals in the world" Great grand father "Never impute planning where incompetence will predict the phenomenon equally well" Father

|

02-10-2013, 09:44 PM

|

|

|

|

Join Date: Jan 2012

Location: Valleyview AB

Posts: 1,376

|

|

So.... To continue on with my original post...

Remember my little comment about starting loads?

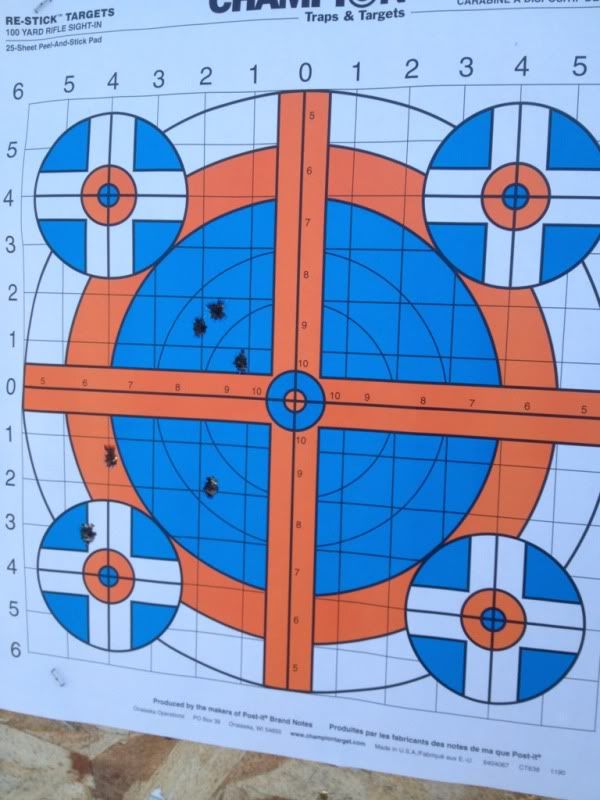

This is why we start at the minamum load and work up, my Lee manual gave me a starting load of 41 grains and a max of 45 grains, at 43.5 grains recoil was pretty stout with an ejector print on my case heads and at 44 grains I was getting a sticky bolt.

But that's ok because things were looking pretty good around 43 grains (3 round group middle left), now that I found a promising charge I will try a slight variation of +\- .2 grains and a few other tricks...

|

02-10-2013, 09:44 PM

|

|

|

|

Join Date: Feb 2012

Posts: 591

|

|

Great thread, thank you.

|

02-10-2013, 09:46 PM

|

|

|

|

Join Date: Feb 2012

Posts: 591

|

|

What does the ejector print look like? I don't see it. lol

|

02-10-2013, 09:48 PM

|

|

|

|

Join Date: Dec 2010

Location: Look behind you :)

Posts: 27,843

|

|

One of the most important aspects to reloading is knowing how to detect pressure signs....and also keeping in the back of your mind that there are really very few (if any) safe shortcuts to take.

LC

__________________

|

02-10-2013, 10:46 PM

|

|

|

|

Join Date: Jan 2012

Location: Valleyview AB

Posts: 1,376

|

|

Quote:

Originally Posted by FlareKing

What does the ejector print look like? I don't see it. lol

|

Look close between the 308 and the WIN, see the outline of a circle? It's faint and hard to see in the picture but you can make out the circular shape if you try...

With Winchester primers I have had an issue of not getting much of the typical feedback with over pressure, they most always flatten out and by the time you have flow or "cratering" into the firing pin hole you have a sticky bolt...

Primer distortion is rather fool proof in most cases to spot warning signs of excessive pressure however you should always look at the whole picture for other signs as well, just because my primers looked good in this case and had I assumed my rifle was dirty resulting in a sticky bolt and I had pushed forward into the 44-45 grain test loads there is a real chance I would have damaged my rifle....

This is why it's important for you all to read threads such as these and ask the silly questions without fear of being laughed at... if you don't know you can get hurt.

|

02-10-2013, 10:59 PM

|

|

|

|

Join Date: Feb 2012

Posts: 591

|

|

I do see it. Thank you for pointing it out. And do not worry I am full of silly questions and will ask a ton just for you!

|

02-11-2013, 01:02 PM

|

|

|

|

Join Date: Oct 2010

Location: Near Drumheller

Posts: 7,024

|

|

As much as I don't like Midway, they will not ship up here, they have the best guide to illustrate the various tools that are available;

http://www.midwayusa.com/general.mvc...nning-reloader

|

02-11-2013, 01:28 PM

|

|

|

|

Join Date: Jul 2011

Location: central AB

Posts: 71

|

|

More threads like this would be a great asset to the forum, as opposed to the rant threads!

Great tutorial for the uninitiated and also great responses from those more experienced hand loaders!

Cat

I agree Cat and I thank each and everyone on AO who takes the time to explain thing that they have had experience with , that is how we all benefit and learn.

thanks for the thread Hotwheels81

|

02-11-2013, 09:31 PM

|

|

|

|

Join Date: Jun 2011

Location: Calgary

Posts: 60

|

|

As someone brand spankin' new to reloading, thank you HotWheels and others for this awesome thread!!! Super excited to hand load some rounds for my 7mm!

|

02-12-2013, 01:18 AM

|

|

|

|

Join Date: Jun 2011

Location: Southern Alberta

Posts: 840

|

|

Another future reloader here..... I have ordered the RCBS Rock Chucker kit. It will be a while before everything is set up and ready to roll though! Threads like these are great, as well as having a mentor. I have a good friend to coach me  .

__________________

Fight for the right to be free, never be owned.

-Manowar

|

02-12-2013, 01:58 AM

|

|

|

|

Join Date: Oct 2010

Location: Near Drumheller

Posts: 7,024

|

|

powder mfgr site & online data links

powder mfgr site & online data links

|

02-12-2013, 02:51 AM

|

|

|

|

Join Date: Oct 2010

Location: Near Drumheller

Posts: 7,024

|

|

bullet mfgrs, some have reloading data online

bullet mfgrs, some have reloading data online

|

02-12-2013, 03:48 AM

|

|

|

|

Join Date: Oct 2010

Location: Near Drumheller

Posts: 7,024

|

|

Some info on Primers

Some info on Primers

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -6. The time now is 12:10 PM.

|